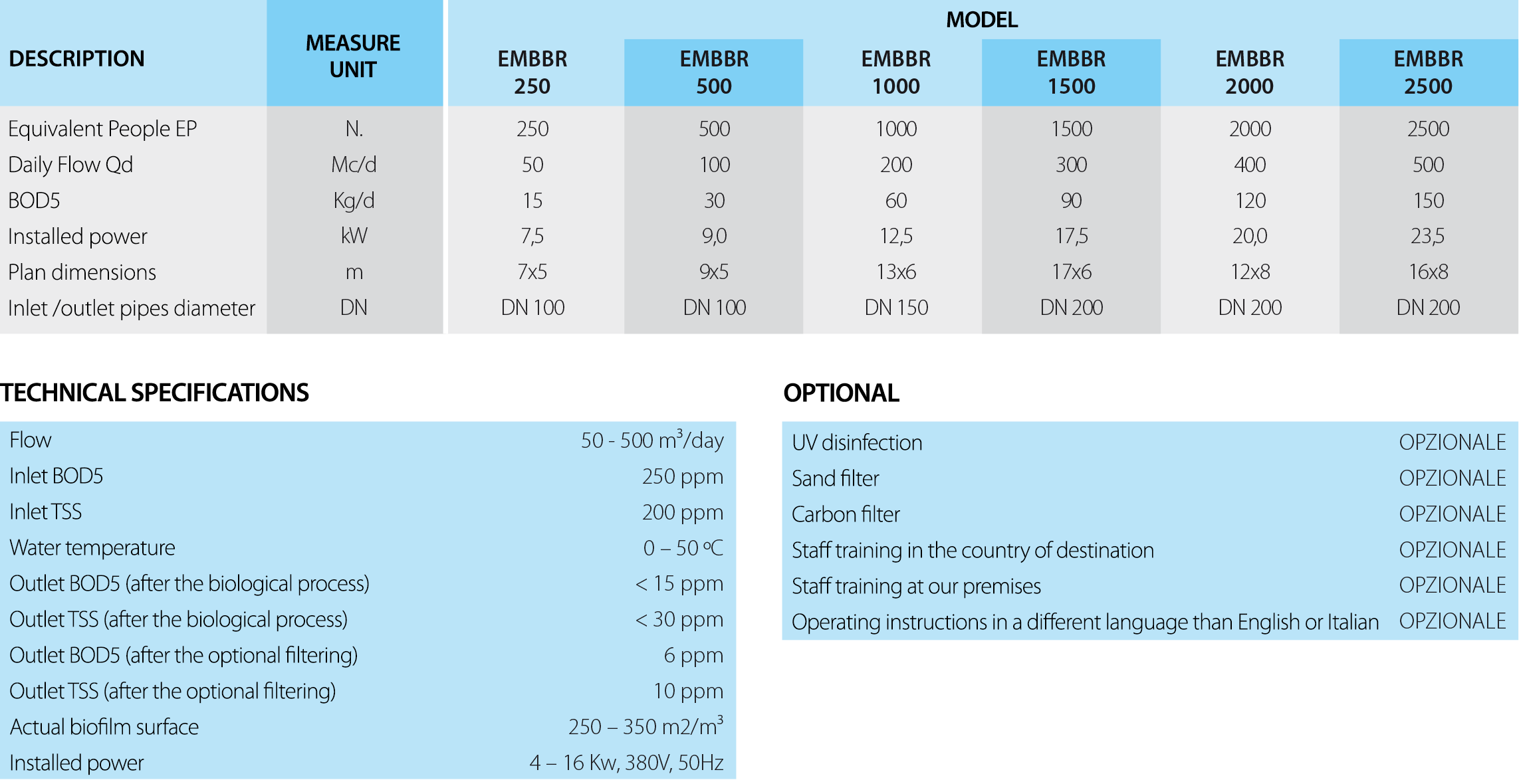

Prefabricated plants for sewage water purification

Sewage water treatment plant MBBR

Capacity: 50 - 500 m³/day

Capacity: 50 - 500 m³/day

Treatment process

The sewage water treatment plant type EMS Water Technology series EMBBR is modular with independent sections, designed to receive sewage water coming directly from sewers or septic tanks.

The process consists of the following sections:

· Pre-treatment

· Denitrification on mobile bed

· Aerated biological oxidation on mobile bed

· Lamellar packs final clarification

· Sludge recirculation

· Reagents dosing

· General control electrical panel

Pre- treatments

The pre-treatment consist of a fine sieving system aimed at keeping the large-medium sized materials thus preventing them to enter the installation and causing malfunctioning to the devices installed . The standard installation includes a drum filter with an AISI 304 steel structure.

Denitrification section

A dedicated denitrification section is necessary to reduce the TKN. The NH4 part contained into the TKN, becomes NO2 (nitrates) and subsequently NO3 (nitrites) as soon as it gets in contact with the oxygen contained into the oxidation tank . Subsequently, after the oxidation section treatment, the sewage water does not contain TKN but nitrates. The nitrates can be removed by recirculating the sewage water into a denitrification zone containing bacteria, decomposing NO3 into: N2 (nitrogen gas) and O2 (oxygen) which the bacteria use to breathe.

Aerated biological oxidation phase

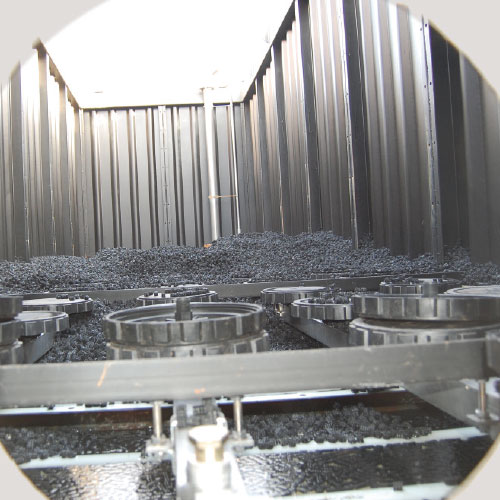

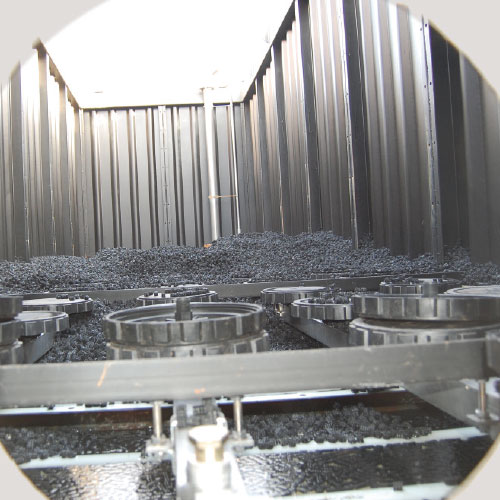

This technology is based on a bio adhesive process named MBBR (Moving Bed Biofilm Reactor). This process is based on the use of plastic material supports , kept suspended and continuously moving into the treatment reactor by the means of air compress insufflation . The excess biomass detaches from the support and is sent to the subsequent final sedimentations section together with the sewage.

the heart of the process consists of the large surface biofilm support elements onto which the microorganisms performing the biological treatment of the polluting organic substances grow.

The electrical blowers supply oxygen in the form of micro bubbles by the membrane diffusers located onto the tank bottom. The oxidation section is designed with a suitable volume to allow the complete mineralization of the contained sludge .

Phosphates removal

The residual phosphorous is removed by the means of a coagulant which will be dosed by suitable dosing pumps directly into the oxidation tank before the final sedimentation treatment, The chemical precipitation allows the abatement of the residual phosphorous, which will deposit by gravity onto the bottom of the final sedimentation tank.

Lamellar pack final sedimentation tank

The aerated sewage contained in the oxidation tank is sent by gravity to the final clarifier. The clarifier is a particularly shaped tank that, under calm conditions, allows the sludge flakes to settle and therefore a separation between clarified water and sludge . the sewage passes through the lamellar pack channels with a low speed ascending flux, helps the suspended substances to sediment which, by gravity fall onto the bottom while the sewage thus clarified reaches the tank surface to be subsequently discharged .

Sludge recirculation

The active sludge, collected onto the bottom of the sedimentation section, are sent again to the oxidation phase by the means of an electro pump.

Sludge extraction

The excess sludge extractions is carried out by a specific manual valve located onto the sludge recirculation line.

Transportation

This sewage water treatment plants type EMS Water Technology with MBBR technology are conceived to be easily displaced in the Italian territory since their dimensions are compatible with road. standard container or flat rack transportation.

The sewage water treatment plant type EMS Water Technology series EMBBR is modular with independent sections, designed to receive sewage water coming directly from sewers or septic tanks.

The process consists of the following sections:

· Pre-treatment

· Denitrification on mobile bed

· Aerated biological oxidation on mobile bed

· Lamellar packs final clarification

· Sludge recirculation

· Reagents dosing

· General control electrical panel

Pre- treatments

The pre-treatment consist of a fine sieving system aimed at keeping the large-medium sized materials thus preventing them to enter the installation and causing malfunctioning to the devices installed . The standard installation includes a drum filter with an AISI 304 steel structure.

Denitrification section

A dedicated denitrification section is necessary to reduce the TKN. The NH4 part contained into the TKN, becomes NO2 (nitrates) and subsequently NO3 (nitrites) as soon as it gets in contact with the oxygen contained into the oxidation tank . Subsequently, after the oxidation section treatment, the sewage water does not contain TKN but nitrates. The nitrates can be removed by recirculating the sewage water into a denitrification zone containing bacteria, decomposing NO3 into: N2 (nitrogen gas) and O2 (oxygen) which the bacteria use to breathe.

Aerated biological oxidation phase

This technology is based on a bio adhesive process named MBBR (Moving Bed Biofilm Reactor). This process is based on the use of plastic material supports , kept suspended and continuously moving into the treatment reactor by the means of air compress insufflation . The excess biomass detaches from the support and is sent to the subsequent final sedimentations section together with the sewage.

the heart of the process consists of the large surface biofilm support elements onto which the microorganisms performing the biological treatment of the polluting organic substances grow.

The electrical blowers supply oxygen in the form of micro bubbles by the membrane diffusers located onto the tank bottom. The oxidation section is designed with a suitable volume to allow the complete mineralization of the contained sludge .

Phosphates removal

The residual phosphorous is removed by the means of a coagulant which will be dosed by suitable dosing pumps directly into the oxidation tank before the final sedimentation treatment, The chemical precipitation allows the abatement of the residual phosphorous, which will deposit by gravity onto the bottom of the final sedimentation tank.

Lamellar pack final sedimentation tank

The aerated sewage contained in the oxidation tank is sent by gravity to the final clarifier. The clarifier is a particularly shaped tank that, under calm conditions, allows the sludge flakes to settle and therefore a separation between clarified water and sludge . the sewage passes through the lamellar pack channels with a low speed ascending flux, helps the suspended substances to sediment which, by gravity fall onto the bottom while the sewage thus clarified reaches the tank surface to be subsequently discharged .

Sludge recirculation

The active sludge, collected onto the bottom of the sedimentation section, are sent again to the oxidation phase by the means of an electro pump.

Sludge extraction

The excess sludge extractions is carried out by a specific manual valve located onto the sludge recirculation line.

Transportation

This sewage water treatment plants type EMS Water Technology with MBBR technology are conceived to be easily displaced in the Italian territory since their dimensions are compatible with road. standard container or flat rack transportation.