Vacuum sewage system

Advantages of the vacuum sewage system

The characteristics and performances guarantee by the vacuum sewage systems type EMS Water Technology permit to resolve a series of surmountable problems otherwise solvable only with higher costs. The choice of an alternative system involves a series of direct and additional advantages.

• USE OF SMALL DIAMETER, LIGHT, RESISTANT, LASTING AND EASY-LAYING PIPES

• REDUCED DIMENSION OF THE EXCAVATIONS, BOTH IN WIDTH AND IN DEPTH

• MINIMIZATION OF THE ENVIRONMENTAL IMPACT CAUSED BY THE LAYING WORKS OF THE PIPES

• IN CASE OF EXCAVATION WITH GROUND WATER, REDUCTION OR ELIMINATION OF THE COSTS FOR WELL-POINT

• ABSOLUTE ABSENCE OF INFILTRATIONS AND LEAKAGES ALONG THE LINES

• CONNECTION AT THE CONSUMPTIONS SIMPLY WITH SHORT GRAVITY COLLECTOR

• ELIMINATION OF THE INSPECTION SHAFTS

• POSSIBILITY TO OVERCOME COUNTERSLOPES

• POSSIBILITY TO AVOID OR OVERCOME KNOWN OR

• UNEXPECTED OBSTACLES ALONG THE COURSE OF THE PIPE

• ELECTRICAL CONNECTIONS LIMITED ONLY TO THE VACUUM CENTRAL

• INSTALLED GLOBAL POWER REDUCTION

• ELIMINATION OF BLOCKS AND SEDIMENTATIONS: THE SYSTEM IS SELF-CLEANING

• FLEXIBILITY OF THE PLANT INSTALLATION WHICH CAN BE EASILY AND ECONOMICALLY ENLARGED AND DEVELOPED

• EASE OF INTEGRATION WITH THE TRADITIONAL SEWER SYSTEM EXISTING

• REALIZATION OF A SEPARATE SEWERAGE SYSTEM WITH MINIMUM INSTALLATION AND EXERCISE COSTS

The characteristics and performances guarantee by the vacuum sewage systems type EMS Water Technology permit to resolve a series of surmountable problems otherwise solvable only with higher costs. The choice of an alternative system involves a series of direct and additional advantages.

• USE OF SMALL DIAMETER, LIGHT, RESISTANT, LASTING AND EASY-LAYING PIPES

• REDUCED DIMENSION OF THE EXCAVATIONS, BOTH IN WIDTH AND IN DEPTH

• MINIMIZATION OF THE ENVIRONMENTAL IMPACT CAUSED BY THE LAYING WORKS OF THE PIPES

• IN CASE OF EXCAVATION WITH GROUND WATER, REDUCTION OR ELIMINATION OF THE COSTS FOR WELL-POINT

• ABSOLUTE ABSENCE OF INFILTRATIONS AND LEAKAGES ALONG THE LINES

• CONNECTION AT THE CONSUMPTIONS SIMPLY WITH SHORT GRAVITY COLLECTOR

• ELIMINATION OF THE INSPECTION SHAFTS

• POSSIBILITY TO OVERCOME COUNTERSLOPES

• POSSIBILITY TO AVOID OR OVERCOME KNOWN OR

• UNEXPECTED OBSTACLES ALONG THE COURSE OF THE PIPE

• ELECTRICAL CONNECTIONS LIMITED ONLY TO THE VACUUM CENTRAL

• INSTALLED GLOBAL POWER REDUCTION

• ELIMINATION OF BLOCKS AND SEDIMENTATIONS: THE SYSTEM IS SELF-CLEANING

• FLEXIBILITY OF THE PLANT INSTALLATION WHICH CAN BE EASILY AND ECONOMICALLY ENLARGED AND DEVELOPED

• EASE OF INTEGRATION WITH THE TRADITIONAL SEWER SYSTEM EXISTING

• REALIZATION OF A SEPARATE SEWERAGE SYSTEM WITH MINIMUM INSTALLATION AND EXERCISE COSTS

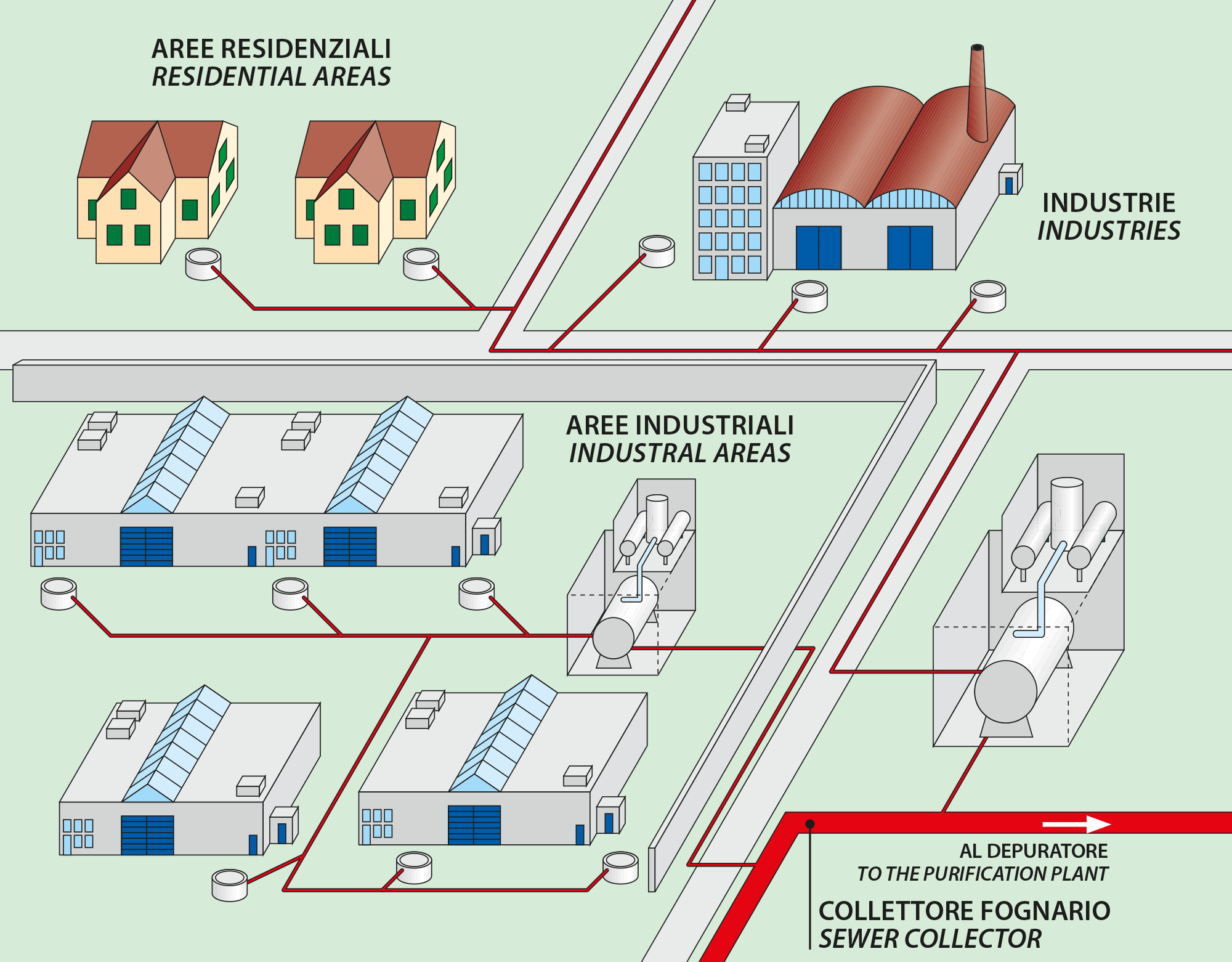

Centralized vacuum sewage plant

The Vacuum sewage system (otherwise defined vacuum-sealed) uses the vacuum created inside a network of pipelines for the collection of sewage water and for their carriage to a final station. The system uses the vacuum technology as a method of waste water transport; its great flexibility permits to exploit the advantages in those applications where the traditional methods are too expansive or unsuitable. The vacuum sewage plant represents a solution for a centralized collection system at reasonable costs.

Application of the system

• CONSTRUCTION OF A NEW SEWAGE NETWORK

• COMPLETION OF EXISTING SEWAGE NETWORKS

• EXTENSION OF THE SEWAGE NET AT ISOLATED INHABITED UNITS

• SUBSTITUTION OF OBSOLETE AND INADEQUATE NETWORK

• SEPARATION OF WASTE WATER COLLECTION NETWORKS

• HISTORICAL CENTERS WITH PARTICULAR CHARACTERISTICS

• WASTES COLLECTION IN INDUSTRIAL AREAS

• HOSPITAL CENTERS

• TOURIST PORTS

• EQUIPPED SERVICE AREAS

• EXHIBITION CENTERS

• COMMERCIAL CENTERS

• RECREATIONAL CENTERS

• TOURIST VILLAGES

• COASTAL URBANIZATIONS

• CAMPINGS

The Vacuum sewage system (otherwise defined vacuum-sealed) uses the vacuum created inside a network of pipelines for the collection of sewage water and for their carriage to a final station. The system uses the vacuum technology as a method of waste water transport; its great flexibility permits to exploit the advantages in those applications where the traditional methods are too expansive or unsuitable. The vacuum sewage plant represents a solution for a centralized collection system at reasonable costs.

Application of the system

• CONSTRUCTION OF A NEW SEWAGE NETWORK

• COMPLETION OF EXISTING SEWAGE NETWORKS

• EXTENSION OF THE SEWAGE NET AT ISOLATED INHABITED UNITS

• SUBSTITUTION OF OBSOLETE AND INADEQUATE NETWORK

• SEPARATION OF WASTE WATER COLLECTION NETWORKS

• HISTORICAL CENTERS WITH PARTICULAR CHARACTERISTICS

• WASTES COLLECTION IN INDUSTRIAL AREAS

• HOSPITAL CENTERS

• TOURIST PORTS

• EQUIPPED SERVICE AREAS

• EXHIBITION CENTERS

• COMMERCIAL CENTERS

• RECREATIONAL CENTERS

• TOURIST VILLAGES

• COASTAL URBANIZATIONS

• CAMPINGS

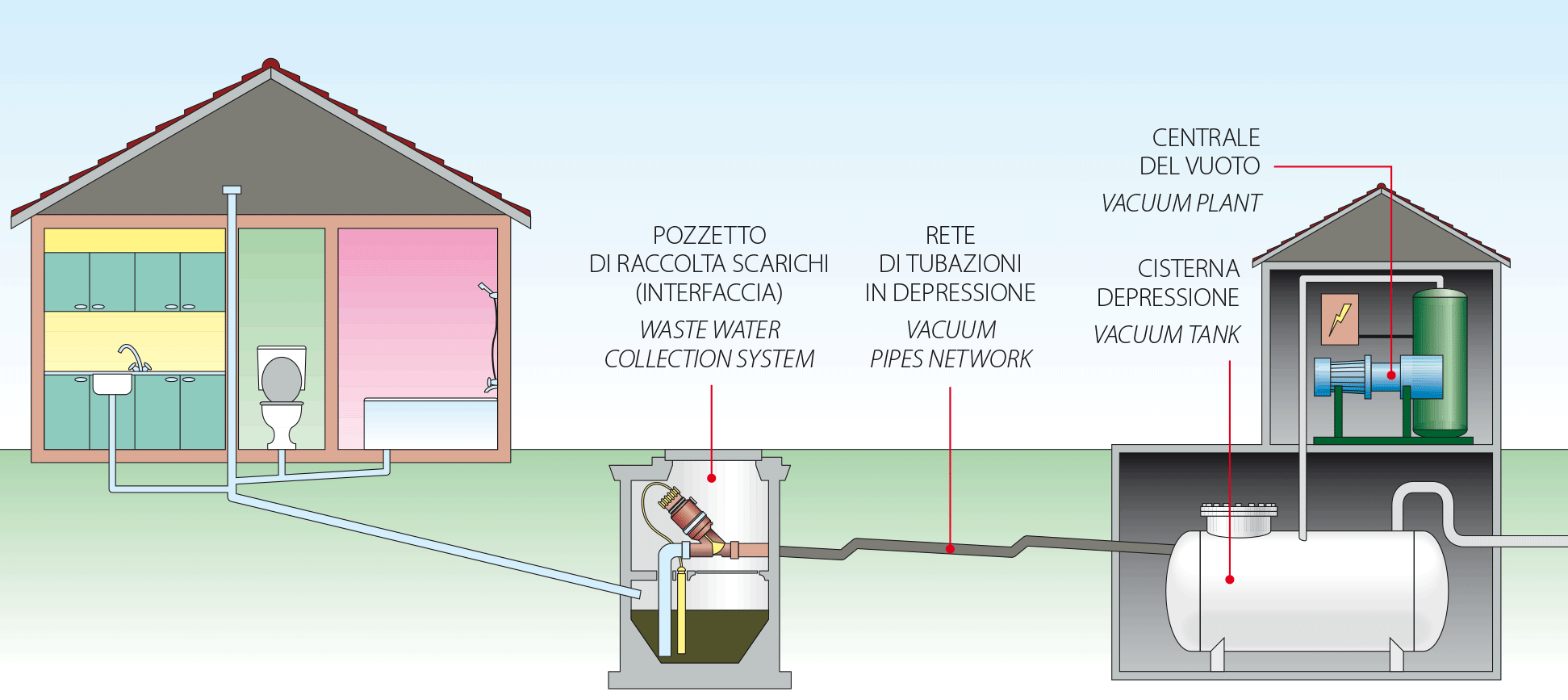

Components of the plant

Connection well

The EMS Water Technology connection wells are constituted by a structure usually made of glassfibre, HDPE or concrete connected with the gravity domesticsewerage. The wells are equipped with an automatic valve (interface valve) which, when the sewage in the well reaches a preset level, it opens putting in communication the same well with the vacuum collector. The valve remains open for enough time to guarantee the suction of all the sewage and of a certain quantity of air. The air introduction of the vacuum system is essential to guarantee the transport of the sewage. The sewage aspirated by different connection wells is transferred to the final collecting station through a network permanently kept in vacuum through a vacuum generation system located in the forward extremity of the same network. The aspirated sewage is introduced in the collector as liquid buffer (or plug), which is kept in motion by the vacuum. For the transfer toward the collection point, a technical expedient is used, which consist in creating, all along the collector and at a distance of about 50 meters one from the other, some siphons (denominated transport pockets), in which the sewage flowing inside assumes a potentially favourable shape allowing to bacome one more a plug as soon as newsewage and air are put in the pipeline.

Vacuum station and collection

The EMS Water Technology vacuum collection station constitutes the final part of the plant and has the double function of collecting the sewage coming from the collectors (to be sent by the waste pumps to the chosen delivery point) and to create and to restore the wished vacuum level into the collectors. The collection and vacuum station can be realized according to different plants types. Thecollection tank can be in vacuum or open air, with waste pumps installed in the tank, and provides to lift and to send the sewage at the delivery point, in some plants types solutions waste pumps aren’t necessary.

Connection well

The EMS Water Technology connection wells are constituted by a structure usually made of glassfibre, HDPE or concrete connected with the gravity domesticsewerage. The wells are equipped with an automatic valve (interface valve) which, when the sewage in the well reaches a preset level, it opens putting in communication the same well with the vacuum collector. The valve remains open for enough time to guarantee the suction of all the sewage and of a certain quantity of air. The air introduction of the vacuum system is essential to guarantee the transport of the sewage. The sewage aspirated by different connection wells is transferred to the final collecting station through a network permanently kept in vacuum through a vacuum generation system located in the forward extremity of the same network. The aspirated sewage is introduced in the collector as liquid buffer (or plug), which is kept in motion by the vacuum. For the transfer toward the collection point, a technical expedient is used, which consist in creating, all along the collector and at a distance of about 50 meters one from the other, some siphons (denominated transport pockets), in which the sewage flowing inside assumes a potentially favourable shape allowing to bacome one more a plug as soon as newsewage and air are put in the pipeline.

Vacuum station and collection

The EMS Water Technology vacuum collection station constitutes the final part of the plant and has the double function of collecting the sewage coming from the collectors (to be sent by the waste pumps to the chosen delivery point) and to create and to restore the wished vacuum level into the collectors. The collection and vacuum station can be realized according to different plants types. Thecollection tank can be in vacuum or open air, with waste pumps installed in the tank, and provides to lift and to send the sewage at the delivery point, in some plants types solutions waste pumps aren’t necessary.